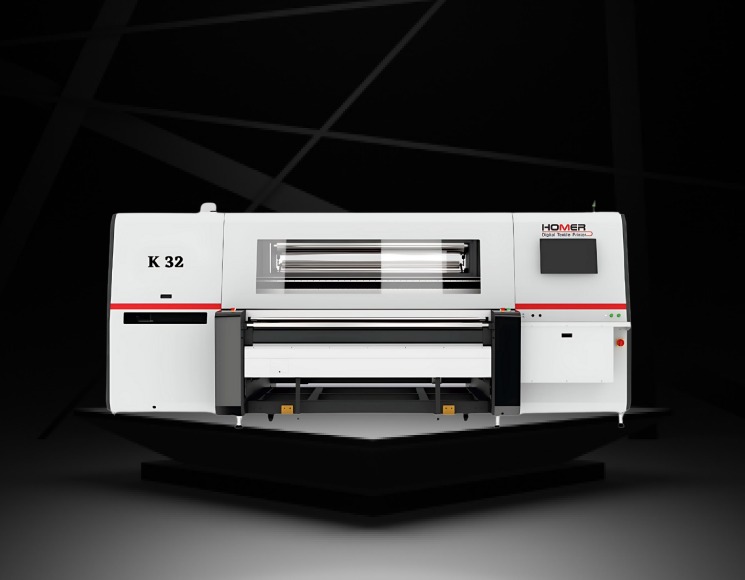

Printers / Homer / K32

K32

The Homer K32 is a high-speed industrial digital textile printer built for large-scale, precision-driven production. With 32 Kyocera printheads, intelligent automation, and vibrant multi-color ink capabilities, it delivers consistent quality and impressive throughput for demanding textile businesses.

Specifications

Head technology

Water-based Kyocera print head

Printing mode

1–4 pass (up to 570 linear meters/hr)

Max Printing Width

1900 mm

Weight

7000 kg | Dryer – 3585 kg

Head Technology – Water-based Kyocera print head

Printing mode – 1–4 pass (up to 570 linear meters/hr)

Max Printing Width – 1900 mm

Weight – 7000 kg | Dryer – 3585 kg

Product Features

Engineered for industrial-scale printing, the K32 combines robust mechanics, intelligent automation, and high-capacity output to deliver consistent, vibrant results with minimal downtime.

Intelligent Head Protection

All-around printhead anti-scratch system extends printhead life and ensures safe fabric handling.

Industrial-Grade Belt System

Stable, deviation-free fabric movement ensures precise registration and smooth output

Visual Operation Interface

Smart UI allows one-person multi-printer management and easy job recovery.

High-Speed Data Processing

Equipped with a large-memory industrial server for fast, uninterrupted data flow.

Explore the Power of K32

Unlock the full potential of K32 and see how it can revolutionize your textile printing workflow. Download the brochure to learn about its advanced features, robust engineering, and how it supports high-speed, high-precision production.

Knowledge Base

Revolutionizing the textile printing industry with technology.

Automatic Moisturizing & Cleaning System

Reduces head wear and extends printer life by keeping printheads in optimal condition.

Excellent Noise Reduction

High-speed linear motor and THK mute rail ensure stable, quiet operation during high-speed runs.

Diaphragm Pump Ink Supply System

Durable and stable ink supply system for consistent performance under continuous production.