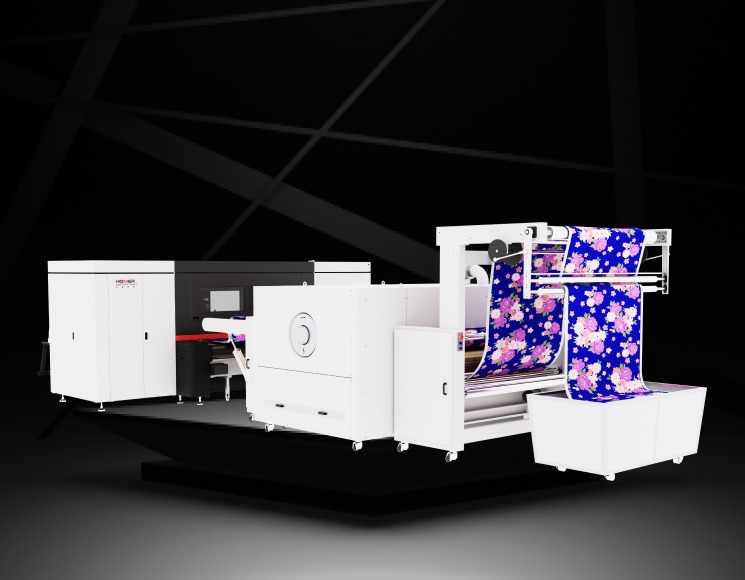

Printers / Homer / K64

K64

The Orange O Tec K64 is a next-generation industrial fabric printer engineered for speed, scale, and sharp precision. With up to 64 high-performance piezoelectric printheads and versatile ink support, it delivers ultra-fast, vibrant prints for high-demand textile production.

Specifications

No. Of Heads

Industrial-grade piezoelectric printheads (32/48/56/64 heads)

Printing mode

1 pass – up to 1100 linear meters/hr

Max Printing Width

1800 mm

Color Config

CMYK + 4 Other Colors

No. Of Heads – Industrial-grade piezoelectric printheads (32/48/56/64 heads)

Printing mode – 1 pass – up to 1100 linear meters/hr

Max Printing Width – 1800 mm

Color Config – CMYK + 4 Other Colors

Product Features

Built for serious textile manufacturers, the K64 offers cutting-edge print precision, advanced material handling, and a wide range of ink compatibility, all packed into a robust, high-output system.

Exceptional Head Chilling System

Ensures stable printhead temperature for reliable high-speed operation.

Ink Misting Control Technology

Reduces overspray and improves print clarity, even at higher resolutions.

Versatile Drying Options

Choose from steam, electric, hot oil, or hybrid systems to suit your production setup.

Adjustable Media Handling

Supports various feeding and outfeed systems including tension unwind and cloth trolley for wrinkle-free output.

Explore the Power of K64

Unlock the full potential of K64 and see how it can revolutionize your textile printing workflow. Download the brochure to learn about its advanced features, robust engineering, and how it supports high-speed, high-precision production.

Knowledge Base

Revolutionizing the textile printing industry with technology.

High-Capacity Ink System

30 L/color tanks support extended runs with minimal intervention.

Multiple Ink Types Supported

Compatible with reactive, pigment, disperse, acid, and even latex inks for a wide range of fabric applications

Flexible Color Configuration

Supports 4, 6, 7, and 8 color modes, customizable to your production and design needs.