Direct-to-fabric (DTF) printing is a modern digital textile printing method that allows high-quality images and designs to be printed directly onto fabric using advanced inkjet technology. Known for its speed, efficiency, and excellent color performance, direct-to-fabric printing has become a preferred solution for small businesses, garment manufacturers, textile suppliers, and customized printing providers.

However, with a wide range of options available in the market, choosing the right direct-to-fabric printer can be challenging. This blog serves as a practical guide to help you understand the key factors to consider when selecting a direct-to-textile printer that best suits your business needs.

Essential Factors to Consider When Choosing a Direct-to-Fabric Printer

1. Cost and Long-Term Value

The cost of a direct-to-fabric printer can range from a few thousand to tens of thousands of dollars, depending on its features, capacity, and technology. While budget is an important factor, the lowest-priced printer may not always deliver the best value. Investing in a high-quality, industrial-grade printer can result in better print consistency, reduced maintenance costs, and higher productivity over time.

2. Print Quality

Print quality is one of the most critical considerations in textile printing. It depends on factors such as printer resolution, ink technology, and fabric quality. Before making a final decision, it is advisable to review the technical specifications provided by the manufacturer and request printed samples. This ensures the printer meets your expectations for color accuracy, sharpness, and fabric performance.

3. Printing Speed and Productivity

For businesses operating at scale, printing speed directly impacts productivity and profitability. Industrial direct-to-fabric printers are designed to deliver high output without compromising quality. For example, Orange O Tec’s advanced direct-to-fabric printers can achieve production speeds of from 2,200 LM/Day to up to 75,000 LM/Day, making them well-suited for high-volume textile manufacturing environments.

4. Maximum Print Size

Different printers support different fabric widths. Before purchasing a printer, ensure that it can accommodate the maximum print size required for your products. Selecting the appropriate print width from the outset helps avoid operational limitations as your business grows.

5. Ink Type Compatibility

Ink selection plays a crucial role in digital textile printing. The most commonly used ink types include:

- Reactive ink

- Acid ink

- Disperse ink

- Pigment ink

Each ink type is suitable for specific fabrics and applications. It is important to consult with the printer supplier to confirm which ink types the printer supports and whether they are compatible with your intended printing materials.

6. Fabric Compatibility

Just as ink type matters, fabric compatibility is equally important. Some printers are designed for specific textiles, while others can handle a wide range of materials such as cotton, silk, polyester, and blended fabrics. Choosing a printer that aligns with your fabric requirements ensures consistent quality and operational flexibility.

7. Operation, Maintenance, and Support

Direct-to-fabric printers are professional-grade printers that typically require trained operators and regular maintenance. It is recommended to invest in a printer that is user-friendly, easy to maintain, and supported by reliable after-sales service. Access to spare parts, technical training, and responsive customer support can significantly reduce downtime and improve overall efficiency.

About Orange O Tec and the Colorix Brand

Orange O Tec, headquartered in Surat, India-one of the world’s leading textile hubs-is a professional digital textile printer manufacturer and supplier. Orange O Tec delivers innovative, high-performance digital textile printing solutions tailored to the evolving needs of the global textile industry.

The company offers a comprehensive portfolio of industrial fabric printers, including:

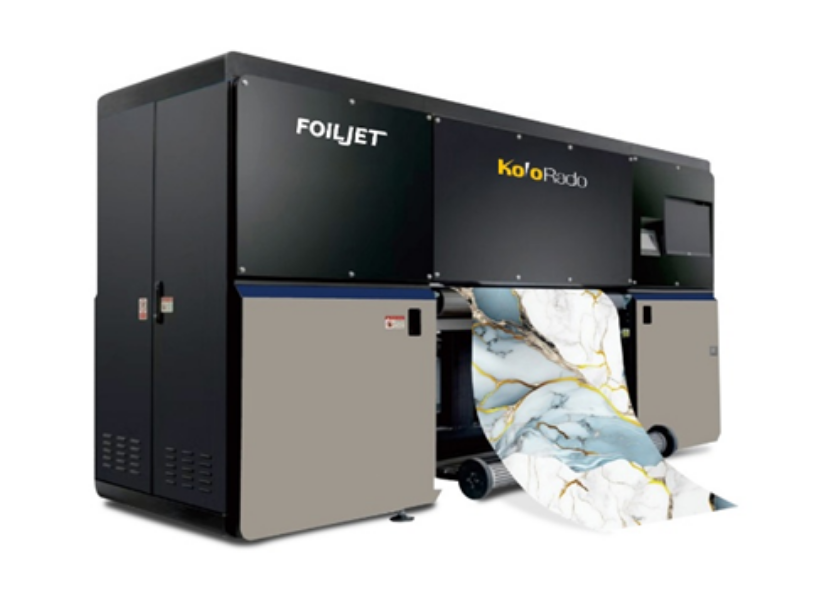

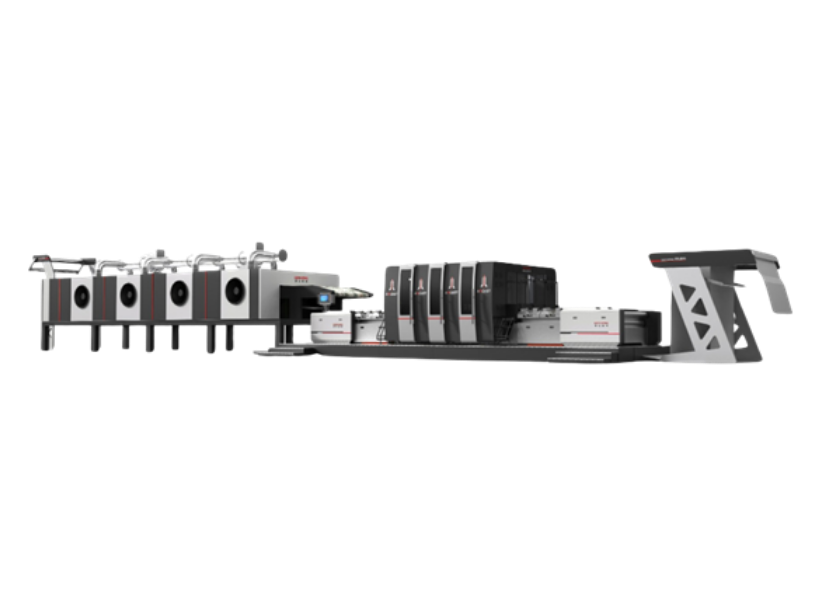

- Homer’s K24, K32, and K64 series, along with the recently launched Rocket

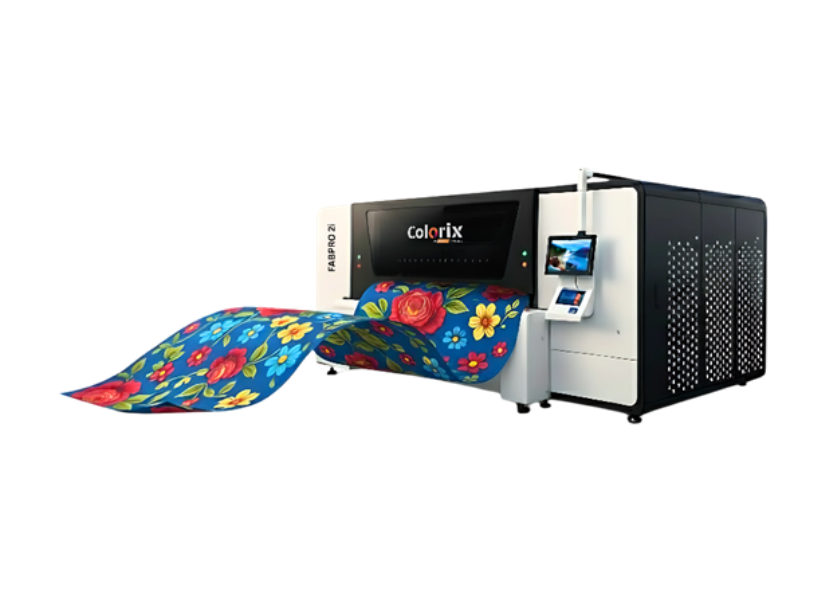

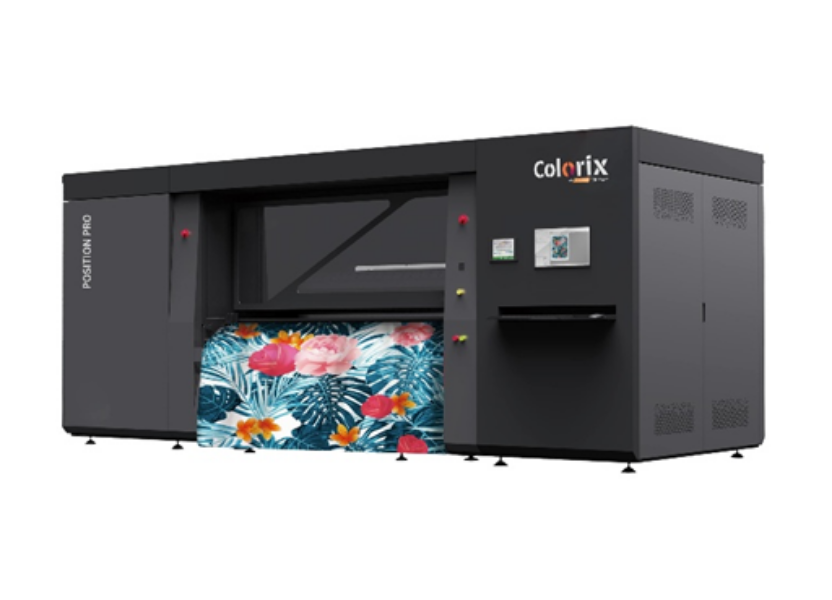

- Colorix’sFabPro series (Made in India) and the recently launched Position Pro Printer

- Kolorados’ sublimation digital textile printers

Each solution is designed to deliver reliability, superior print quality, and high productivity for modern textile businesses.

Conclusion

Direct-to-fabric printing is a powerful and efficient solution for producing high-quality customized textiles. When selecting the right direct-to-fabric printer for your business, it is essential to carefully evaluate factors such as cost, print quality, printing speed, print size, ink type, fabric compatibility, and ease of operation and maintenance.

With the right digital textile printing solution from Orange O Tec, businesses can enhance production efficiency, maintain consistent quality, and gain a competitive edge in today’s dynamic textile market