Digital Positioning Printing is an advanced textile printing technology that uses a high-definition industrial camera integrated directly into the printer. This camera intelligently recognizes existing fabric textures-such as woven patterns, embroidery, sequins, or lace.

A powerful computing system then performs real-time calculations and micro-adjustments, guiding the printheads to spray ink with extreme accuracy onto the exact intended area. The result?

A perfect fusion of design and fabric texture, even on the most challenging materials.

Core Capabilities That Set It Apart

Intelligent Visual Recognition

The system automatically scans the fabric surface, captures texture details, and locks onto precise reference points-no manual alignment required.

Real-Time Dynamic Correction

Microsecond-level adjustments continuously compensate for fabric distortion, ensuring the printing coordinates remain accurate throughout production.

High-Precision, Photo-Quality Printing

With no color limitations and the ability to print complex designs in a single pass, Digital Positioning Printing delivers stunning detail and consistency every time.

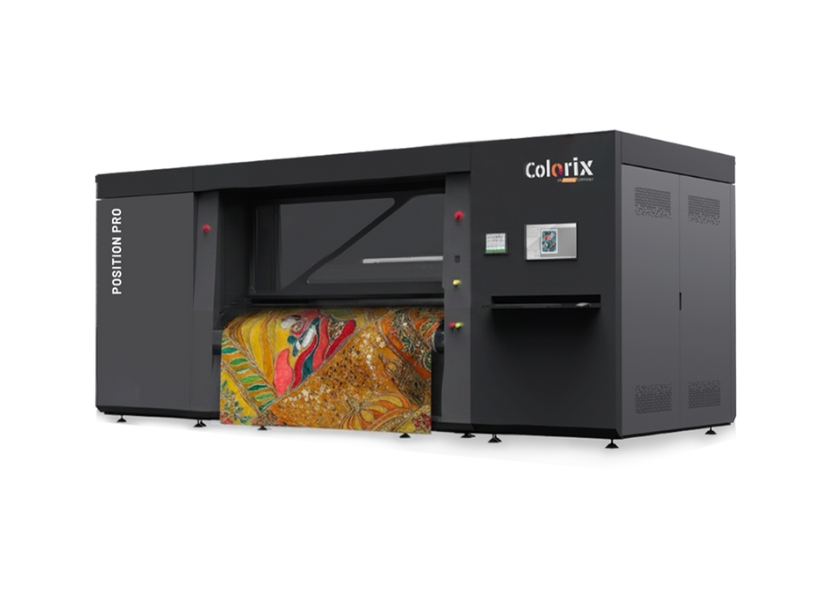

Position Pro: Beyond Positioning Printing

Colorix’s Position Pro printer is not just a printer-it’s a complete solution for high-end, high-volume textile production.

High-Speed Performance

- 16 Kyocera printheads deliver relentless productivity

- Upto 2,000 LM/Day

Ultra-Accurate Visual Positioning

A proprietary vision system masters the most complex textures—jacquard, embroidery, sequins, and lace-ensuring perfect alignment on every print.

Photo-Quality HD Imaging

- Up to 1800 dpi physical resolution

- Intricate patterns, sharp edges, and vibrant, true-to-life colors

Broad Fabric & Ink Compatibility

Supports acid, reactive, and pigment inks, allowing printing on:

- Cotton

- Silk

- Polyester

- Blended fabrics

Intelligent Printhead Protection

Advanced sensor systems protect valuable printheads from scratches and damage—ensuring stable, worry-free production.

Automated & Effortless Operation

From one-touch printhead maintenance to automated belt cleaning, the modular design simplifies daily tasks, reduces labor, and minimizes downtime.

Fabrics That Shine with Digital Positioning Printing

Jacquard Fabric Printing

Precisely maps designs onto intricate woven textures—transforming traditional jacquard into high-end custom fabrics for European and American home textiles and designer fashion.

Embroidery Fabric Printing

Perfectly aligns prints with existing embroidery, enabling art-level, value-added designs for ethnic garments like Saris and Punjabi suits in India.

Sequin Fabric Printing

Accurately recognizes complex sequin and metallic thread textures, enabling seamless pattern extension—ideal for luxury Saris, Lehengas, and stage costumes.

Lace Fabric Printing

Achieve sharp, bleed-free results on delicate openwork lace, creating exclusive fabrics favored by lingerie and bridal markets in Europe, America, and Brazil.

Solving the Biggest Pain Points in Printing Factories

❌ Challenge: Misprints & Misalignment

Traditional printing struggles with fabric distortion and complex textures, leading to costly registration errors.

✅ Solution: Guaranteed Precision

Advanced vision scanning locks onto fabric reference points and compensates for distortion in real time—ensuring perfect alignment on every print.

❌ Challenge: Inconsistent & Inaccurate Color

Maintaining consistent color across batches and reproducing brand-specific hues is a constant struggle.

✅ Solution: Intelligent Color Management

Professional color management software analyzes design files, creates accurate color profiles, and performs real-time calibration.

High-precision ink mixing ensures superior color consistency and saturation.

❌ Challenge: Production Bottlenecks & Delays

Screen making, calibration, and slow printing speeds delay delivery—especially for complex designs.

✅ Solution: Accelerated Production Workflow

- Quick pattern changeover

- Automatic parameter settings

- High-speed drive systems and precision mechanics

Together, these features dramatically shorten setup time and boost output.

❌ Challenge: Wasted Materials & Rising Costs

High defect rates, material waste, heavy labor dependence, and frequent maintenance increase costs.

✅ Solution: Reduced Waste & Lower Costs

- High-precision printing reduces defect rates

- Accurate color management minimizes material waste

- Automation lowers labor costs

Stable equipment reduces downtime and maintenance expenses

The Future of Textile Printing Is Here

Digital Positioning Printing is more than an innovation-it’s a game-changer for textile manufacturers aiming for precision, creativity, and profitability. By seamlessly merging intelligent vision, high-speed performance, and flawless color control, it empowers factories to produce premium fabrics with confidence and efficiency.