Modern digital fabric printing has revolutionized the textile industry by eliminating the need for traditional plate making, plate printing, and repetitive color registration. Unlike conventional methods, digital printing requires only a single printer and a standard computer, allowing one operator to manage the entire printing process independently.With these advantages, many businesses are turning to digital fabric printers-but choosing the right printer can be challenging. To simplify your decision, here’s a 3-step checklist to find the perfect digital fabric printer.

Step 1: Identify the Materials You will Be Printing On

The first and most critical step in selecting a digital fabric printer is understanding the materials you will be working with. Different fabrics require different printing approaches, and choosing the right printer depends heavily on this factor.

- Polyester: Polyester is common in sportswear, shower curtains, and tapestries.

- Other fibers: Fashion and home décor industries often use a variety of materials, including cotton, silk, nylon, viscose, and linen.

The type of fiber and the construction of the fabric-whether woven or knit-will influence which ink and printer are best suited for your printing needs. A clear understanding of your fabric materials ensures that your equipment purchase aligns with your production requirements.

Step 2: Identify the Right Ink Chemistry

Selecting the appropriate ink is essential for achieving high-quality, durable prints. Each fabric type reacts differently to various ink chemistries, so understanding the options is critical. The main types of inks for digital textile printing include:

- Reactive Ink: Best for cellulose fibers like cotton and hemp, as well as silk and wool.

- Acid Ink: Ideal for silk, nylon, wool, and other protein-based fabrics.

- Disperse Ink: Suited for polyesterand polyamide fabrics.

- Pigment Ink: Compatible with most textile materials, offering versatility across fabric types.

Choosing the right ink ensures vibrant colors, excellent print quality, and long-lasting results.

Step 3: Choose the Right Digital Fabric Printer

After determining your fabric materials and ink type, you can narrow down your printer options. Digital fabric printers generally fall into two categories:

- Direct-to-Fabric Printers: Print directly onto the fabric and are essential for non-polyester fibers such as cotton, nylon, Lycra, rayon, silk, leather, denim, flax, wool, elastic fabrics, and new fiber blends.

- Sublimation Textile Printers: Best suited for polyester fabrics and specialized high-temperature applications.

Recommended Direct-to-Fabric Printer Models

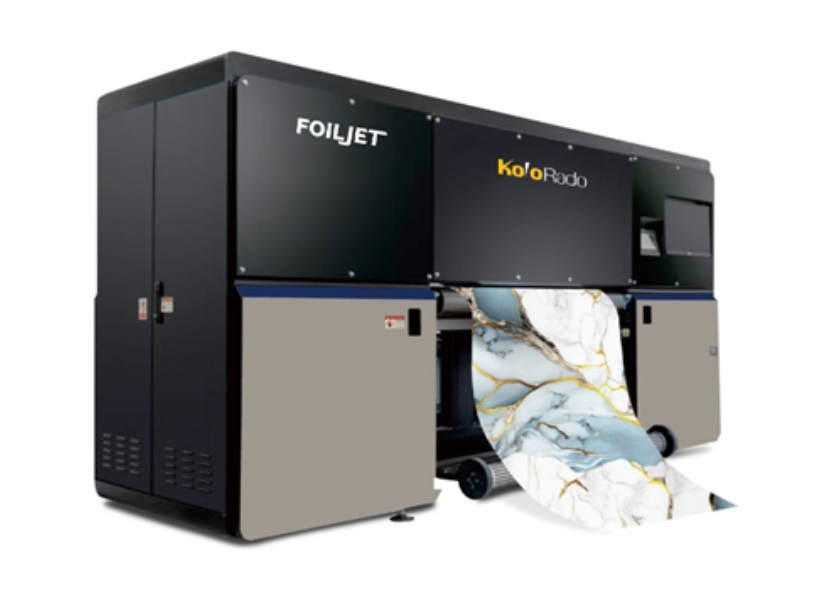

Sublimation textile printers use disperse inks to print on transfer paper, which is then heat-pressed onto the fabric. Sublimation digital textile printers can produce seamless, detailed patterns with vibrant colors. The excellent print quality enhances the consumer’s experience and helps industry users achieve a win-win situation in terms of both quality and cost.

Recommended Sublimation Printer Models